Infinitum Electric PCB Motor Will Get Its First Automotive Application

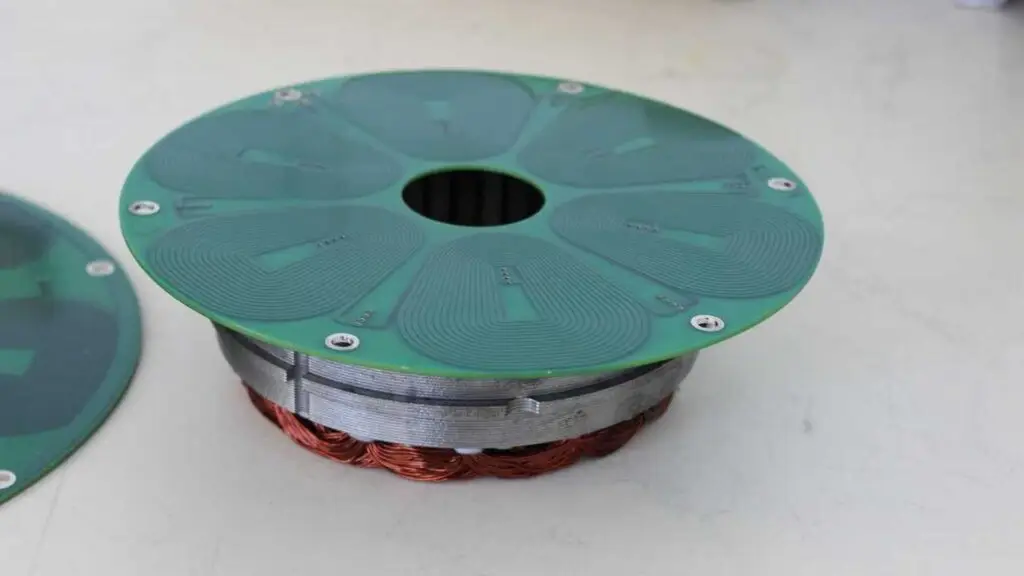

When we first spoke about Infinitum Electric, back in December 2019, it was an amazing promise in terms of efficiency and saving natural resources. Ben Schuler, the company’s founder, came up with the idea of creating an electric motor with printed circuit boards. That PCB motor – now called IEm – was fast in receiving its first application in cars: Infinitum Electric just announced a “leading US automotive supplier” will use it.

To be more precise, what this supplier will do is validate the performance of this revolutionary motor “using oil cooling techniques.” Current versions of the IEm are air-cooled. After that, Infinitum Electric will build a “purposefully designed motor for hybrid assist powertrains.”

Schuler told InsideEVs more about that.

“This will be the main motor providing power to the wheels. They will also provide regenerative power which charges the battery during braking. It will be the main motor for the hybrid assist powertrain.”

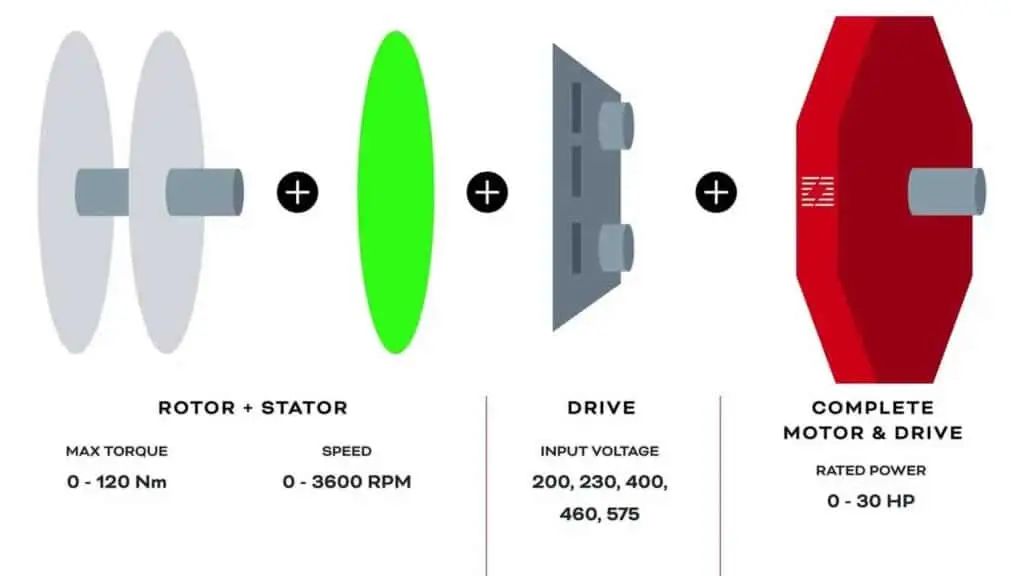

He also summed up the advantages the IEm presents when compared to traditional electric motors.

“The IEm motor is smaller, lighter, quieter and more efficient than the existing motor used for hybrid assist.”

Infinitum Electric’s CEO also explained the steps until its PCB motor reaches production lines inside a vehicle.

“This specific project is a feasibility study to see how the PCB stator reacts with oil cooling techniques. Our existing motor, with passive air over cooling, already has a power density in the range of 3 to 5 kW/kg. Adding active cooling methods like a traditional high power EV motor has, the power density can increase up to 12 kW/kg.”

Although there are still some months or even years before we can buy the IEm in any car, Schuler is optimistic about it.

“The development cycle for automobiles is long, but this is the first critical step to entering this market. Phase 2 is to specifically design a motor rated for the car and to integrate our system into the automobile and continue testing.”

Apart from saving copper and iron, the IEm stator is about 90 percent lighter than that on a regular electric motor with the same power specifications. It is also 15 percent cheaper. If these advantages were not enough, it also does not have cogging torque – which helps extend transmission life – is 15 dB more silent than an iron core motor and is at least 2 percent more efficient than a regular electric motor, which already has a 95 percent efficiency rate.

Schuler also told us the PCB motor is easy to manufacture wherever automakers need them. Not only when it comes to manufacturing, but also designing and developing it. According to the Infinitum Electric CEO, its AutoFlux motor design software enables users to “input application requirements, evaluate design options based on cost and performance, and create PCB design files within minutes.”

It is no surprise this “leading US automotive supplier” wants to learn more about the PCB motor Infinitum Electric developed. For the record, we asked which one it is, but Schuler cannot disclose that now. When he can, we won’t be shocked if it eventually becomes the standard in an industry with efficiency and environmental concerns as some of its most important principles.