The push for e-powertrain progress

by CHRIS CLONTS

Upstarts and heavy-hitter suppliers alike are fast-tracking advances in existing e-propulsion technology — as well as radical new solutions.

Electric powertrain development continues at a fervent pace as OEMs, suppliers and startups try to optimize current technology while forging ahead into new areas. Although battery engineering and development enjoys almost daily industry discussion, traction motor and power electronics remain the investment focus of many established and startup suppliers, as efficiencies gained in these systems can significantly reduce an EV’s required amount of expensive battery capacity.

It’s a rapidly expanding market, seemingly with plenty of room for myriad new players and fresh ideas. Take Vitasco Technologies, the powertrain supplier spun from Continental in 2019, which put a stake in the ground to say all future development would be in support of electrification. As a result, it generated $888 million in revenue in 2021 and Thomas Stierle, head of the Electrification Solutions division, said the company expects revenue to increase to $10 billion to $12 billion by 2030.

The Schaeffler Group’s North American executives said at a corporate technology showcase in fall 2022 that although the company intends to divide its near-term investments at a roughly 50/50 ratio between internal-combustion and electrification development, Schaeffler acknowledges the future is electric and is driving hard on designs to squeeze more efficiency from traction motors and their associated systems. “Electricity is the right choice,” said Patrick Lindemann, president, e-mobility and chassis systems. “There is no doubt.” Getting there means companies are stretching current technology and introducing new motor and power-electronics designs. Drive motors and electronics already are efficient, but there’s massive investment underway for innovations to get even more from the limited onboard power EVs can carry. A selection of recent developments:

Infinitum: Continuing the drive for smaller and lighter motors

Infinitum achieves what it says is a 50% smaller and lighter axial-flux motor by pulling all the iron out of the core and the copper windings from the stator, replacing it all with a printed circuit board (PCB) stator with etched copper conductors. Ben Schuler, founder and CEO of the seven-year-old Austin-based company, said the company’s design eliminates all the core losses — such as from torque ripple, cogging, stator hysteresis and eddy current — from the stator, resulting in “drastically higher efficiency.” It’s smaller, quieter, and more efficient, with higher efficiency over the whole operating curve of the motor,” he said, adding that in a traditional motor, that core loss always is there and it gets worse at higher RPMs. Infinitum, which initially sought to tackle inefficient HVAC motors, is concentrating on industrial markets, which Schuler says can help the company grow because of the relatively quick development cycles (compared to automotive’s typical years- or decades-long cycles) that lead to immediate revenue. He also said it’s a big opportunity to help save energy, as 50% of the world’s power goes to driving electric motors.

The company produced 5,000 motors in 2022 and is projected to deliver 50,000 this year and 150,000 in 2024. Those are for industrial HVAC units, compressors and material-handling applications. Current partners include Rockwell, Caterpillar and Chevron. At CES 2023 in January, Infinitum announced its latest step forward. Its Air-Core motor, paired with the PCB stator, is a liquid-cooling system that channels coolant directly to the motor’s heat source. “We inject the coolant into a hollow shaft and release it over the entire area of the stator. That lets us get four to five times the power density of a traditional radial-flux motor,” Schuler asserted. Most other cooling methods on radial and axial-flux motors only get coolant into a jacket around the motor. Once Infinitum’s system gets coolant to the center of the stator, centrifugal force pushes the liquid to an outer jacket, where it drains into a sump to be recirculated. The result is a motor with 150 kW (201 hp) continuous and 300 kW (402 hp) peak power that runs with 95% efficiency at 7500 RPM.

Schuler wanted to be clear: “We’re not the first to develop a PCB stator, but we are the first to productize it in an effective way for a market.” The company, which holds 32 patents with 44 patents pending, believes it is the first to deploy a PCB stator and liquid cooling in the same package. The Air-Core motor uses silicon-carbide MOSFETs to enable switching at a higher speed. “That allows us to overcome the lack of inductance and operate the stator effectively,” he said. The motor also can receive over-the-air updates. The size of the motor, or whether to use multiple smaller motors instead of one larger one, is driven by the application. “There are practically no limits on the technology from the technical perspective,” Schuler said. “We are an axial-flux machine, so we tend to be a larger diameter and a shorter length.” In some industrial applications, it’s far better to have ten 10-hp motors than a fan driven by a single 100-hp motor. He said that having multiples does allow redundancy, helpful in many applications such as eVTOLs.

The Air-Core motor is designed for a circular life cycle. The copper laminate panels are etched using off-the-shelf FR4 glass epoxy as insulation. This results in ten times the reliability of a standard stator, the company said. Why? “All of our copper laminate and insulation has an equal coefficient of thermal expansion. As it heats and cools over and over, it does that at the same rate. That means no mechanical interference is ever created, which means it will never fail,” Schuler said.

As for the ramp-up to the mobility market, which Schuler says could benefit even more than the HVAC market from the Aircore Mobility Motor’s efficiency, the company is willing to license the technology and already has a handful of agreements with OEMs in the commercial trucking, eVTOL and other markets, for which they expect to deliver units in the second and third quarters this year.

Schaeffler: Systems efficiencies

At Schaeffler, historically a provider of stampings and advanced bearings, e-motor development is coming fast and hard. The company is applying its expertise to traction motors that eke more from established materials or achieve more efficiency via a higher degree of systems integration.

Jeff Hemphill, CTO of the Americas, said last fall that Schaeffler is looking to make permanent-magnet motors more efficient by misaligning the magnets, for example. And it also is directing attention to externally excited motors with no magnets. Magnet-less induction motors typically are less efficient, but Schaeffler’s engineers claim externally excited motors can be developed with efficiencies “on par” with a permanent-magnet motor.

The company’s most-recently revealed idea is the “4in1 e-axle, an integration of traction motor, transmission, power electronics – and in an incremental efficiency gain over its 3in1 e-axle – thermal management. And a collaborative move to SiC power electronics delivers more than 99% efficiency, the company claims.

Schaeffler’s new 4-in-1 e-axle can incorporate a shifting mechanism for a 2-speed transmission, which some believe is a worthwhile addition for the larger, higher inertia-weight vehicles favored in the U.S. market. There also is provision for a decoupling unit

The company isn’t eying only EVs – like many, it believes hybrids will play an important transitional role and is working on improvements for the IC and electric aspects of hybrid architectures. Schaeffler is particularly focused on hardware and electronics to introduce “much higher voltages” for HEVs, said Markus Steinberger, director e-mobility R&D.

ZF: An entire powertrain

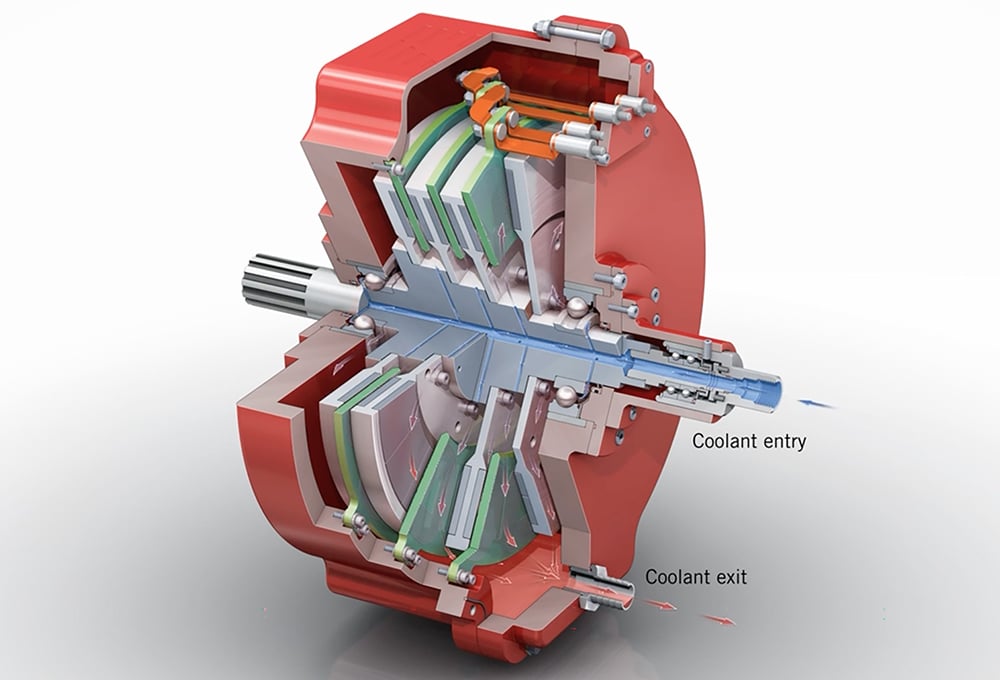

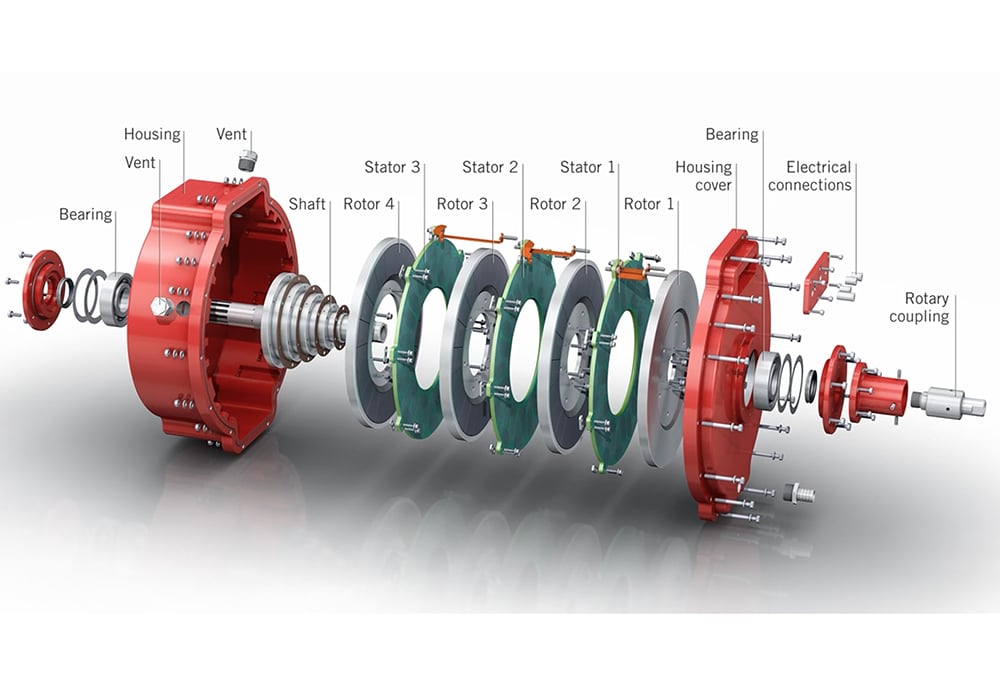

ZF enhances motor power density, system flexibility In November 2022, ZF revealed an all-new electric powertrain with many benefits, but like other contemporary developments is focused on accommodating either 400V or 800V architectures. The flexibility comes from the controller chip and via inverters with individual power switches. The company asserted that this architecture results in fewer components than today’s power modules. The system baselines at 100 kW (134 hp) per axle and can generate as much as 300 kW.

An aspect of ZF’s new e-drive system that’s sure to intrigue competitors is the new technique for braided wiring to increase power density of its systems. “Hairpin wiring, the state of the art today, was introduced five to seven years ago, [and] requires hundreds of laser welding points,” said Roland Hintringer, head of e-motor product lines. He said ZF’s braided wiring is formed and braided in one step, saving time and requiring less space, with a winding head of 15 mm versus 28 mm for hairpin winding. “It only requires 24 welding spots,” he said, adding that the new technique also reduces the raw material used by 10%.

Meanwhile, ZF joins Infinitum in the liquid-cooled stator movement. In addition to the water-cooled motor housing, cooling oil is pumped not only around the stator housing, but also through slots in the braided windings themselves. Hintringer said the result is an 85% increase in peak performance, a 50% increase in power and use of only 1% of the rare earth materials compared to current technology.

eLeap Power: A charger-deleting inverter

eLeap Power also pitched at CES 2023 with a proposition that has unquestionable appeal: The Canadian company says its inverter technology eliminates the need for an onboard charger and voltage converter by leveraging the already existing windings of the drive motor. The result, eLeap said, delivers many benefits:

- 800v charging speeds but compatibility with 400v systems.

- Eliminating the onboard charger reduces vehicle weight by 30-40 kg (66-88 lb.), increasing range.

- Near-universal compatibility with all current EV powertrain architectures. It’s also cost-effective in that it can accomodate 800v architecture while using less-expensive, lower-voltage switching components available today.

- Is fully bidirectional in AC and DC. This allows direct charging of the vehicle battery from renewable resources such as wind and solar, while allowing the vehicle to “give back to the grid” at peak demand times.

- The inverter uses either a split-battery or dual-battery system that results in better reliability. If a part of the system fails, the vehicle remains usable.

Journalists considering eLeap’s innovation may have been skeptical, but Chery Automotive isn’t; eLeap Power is under contract to deliver 15,000 integrated inverters for use in delivery vans made by the Chinese manufacturer.

“Overall, our system is a heck of a lot smarter and more powerful,” said eLeap CEO Russell Pullan. “What they see in our technology is that it allows their vehicle to charge faster, go further with each charge, save costs for manufacturing and end users, and it’s greener.” The heart of the eLeap system is in the way it harnesses the magnetic fields and windings, combined with software, in a motor to “create a very fast flow of electricity to charge the battery.” He said contemporary onboard charger is a major bottleneck and that by eliminating it, charging can be up to three times faster. Project Manager Jonathan Dooley said that in addition to removing the onboard charger, vehicles such as the Lucid Air that are use a 400v/800v boost converter can also eliminate that hardware. “Another one of the ways we’re able to achieve a big cost advantage is that we’re using the motor in the charging operation. So inductors and transformers that would normally be there aren’t necessary,” he said. Pullan put to rest potential concerns about additional wear on the motor. “Charging is motionless, with no rotation of the motor and no vibration.” Dooley acknowledged that others have tried this technology but could not overcome problems. Indeed: SAE Media asked engineers at suppliers and OEMs about eLeap’s technology, and while most did not want to comment on the record, they did say, essentially, “if they’ve figured that out, more power to them.”

Beginning with Chery will speak to another of the benefits about which Pullan is enthusiastic. “If you’re a fleet-logistics company, there are savings per vehicle. We have savings on the OEM costs, but potential savings on infrastructure also. If you have a DC grid in your depot, you don’t need any fast chargers. They’re gone! That saves space. Cherry’s end users, one third of their depot space is taken up by fast chargers. In downtown Chicago or Shenzhen China, that’s [a big cost].”

Even the IP of eLeap’s system is unique, containing more than 50 pieces. Pullan said the core IP, developed with the University of Toronto Electric Vehicle Center, was granted by the U.S. Patent Office with no questions because it is suis generis, a mixture of software, hardware and system architecture not derived from any existing patents.