UPDATE: Infinitum Electric Creates Printed-Circuit-Board-Stator Motor

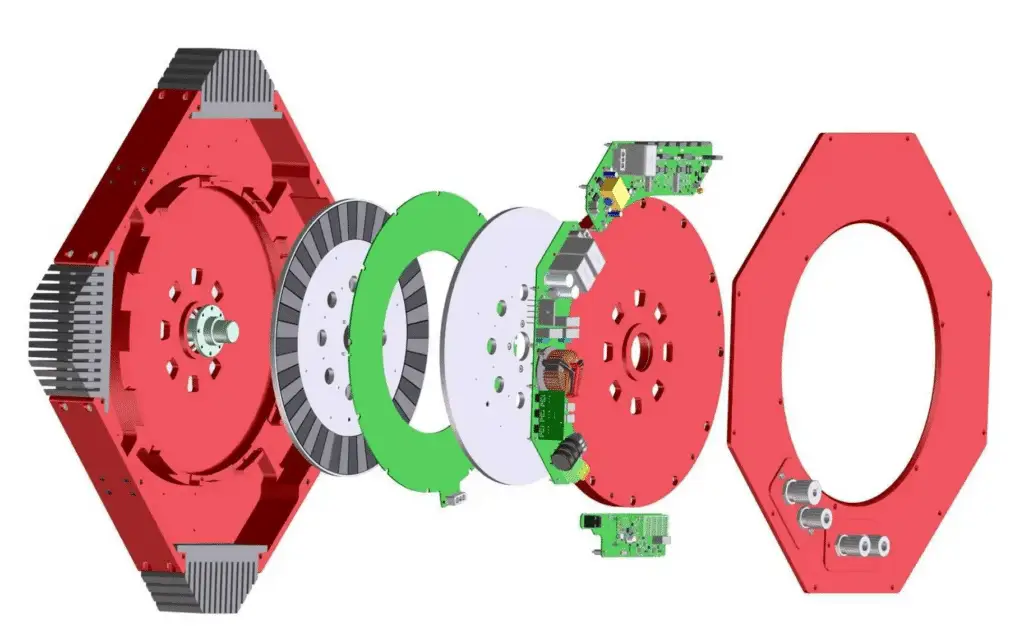

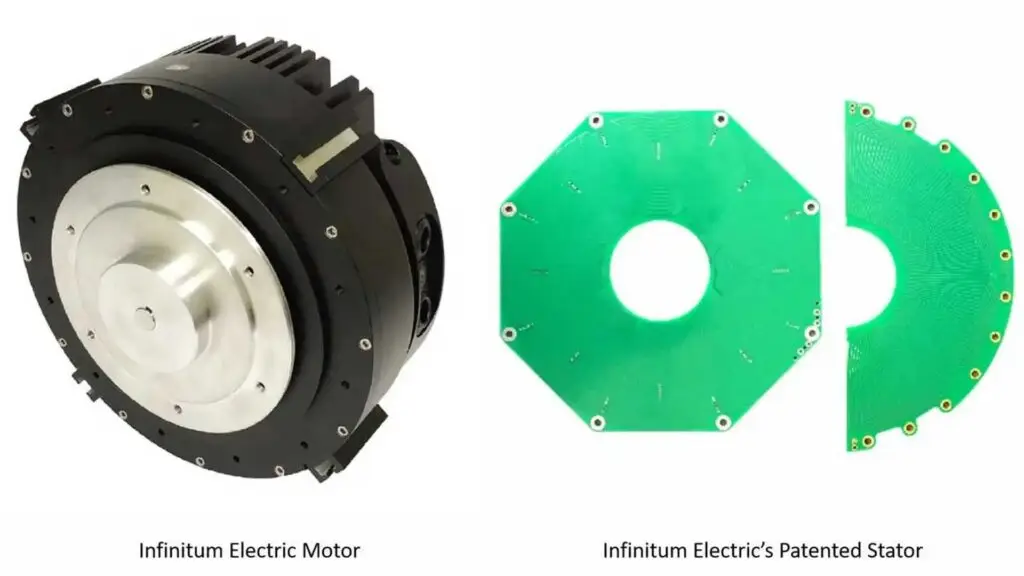

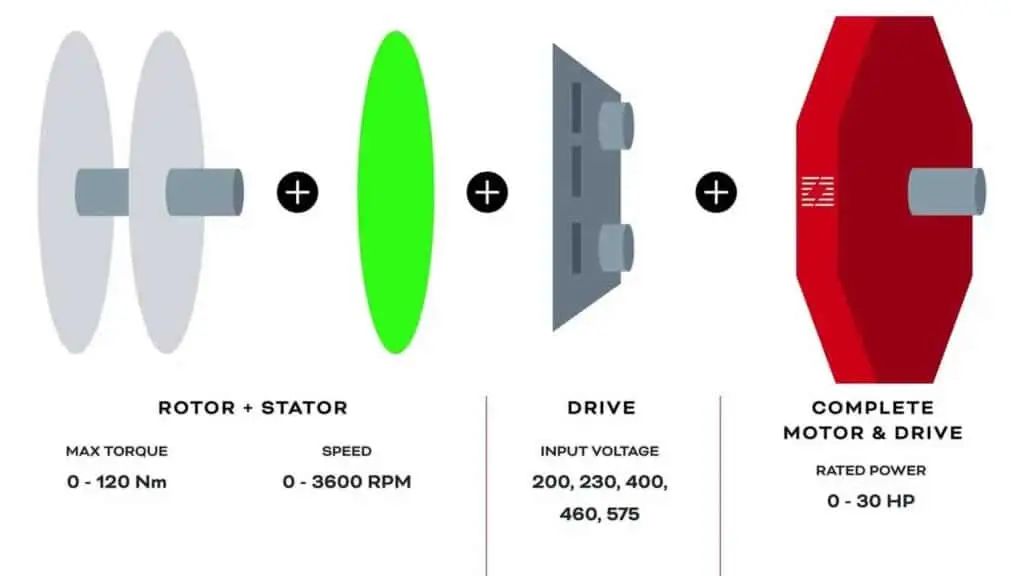

Genius ideas usually are so simple you start to wonder after seeing them: Why did no one think about this before? This is precisely what we felt after seeing what Infinitum Electric has created: a printed circuit board stator. It saves a lot of resources, such as copper and iron. If applied to electric cars, they can help them crucial for a higher range: save mass.

UPDATE: the author misread Ben Schuler on the engine efficiency and made a mistake. The article is now corrected.

Ben Schuler, Infinitum’s CEO, and founder sums that up:

“What our technology does is that it pulls out all the iron and copper windings out of the stator. That pulls out all the losses associated with the core. We then add our copper circuits into a printed circuit board and that makes for a more efficient and more durable stator. What our circuit board does is that it fully installs the entire coil”

Schuler says how lighter it is.

“In an equal comparison, with the exact same power, exact same everything, ours is about 90 percent lighter weight.”

Besides saving resources and weight, the idea of a printed circuit board stator also enables Infinitum Electric to put all sensors on the same piece. The printed board stator also monitors the components. In a regular electric motor, you would have to install sensors separately.

The new motor also claims to eliminate torque ripple, which makes it even more silent than the ones already for sale. The copper conductors are fully insolated, which makes them less prone to failures. But how energy efficient is this breakthrough? Even more than the Magnax?

“It is hard to give you the correct number because the efficiency range depends on the size of the motor. What I can say is that we are at up to 10 percent higher efficiency than equivalent engines. For the ones that are already like 95 percent efficient, we are one or two percent higher. We started our design at a much higher baseline than anyone else. We’ll always be more efficient. Others might be able to match our performance, but only using very rare materials. Ours is cheap, easy to manufacture. Our sales pitch is simple. It is is like: ‘Hey, we’re lighter, we’re cheaper, we have higher efficiency, what else do you need?’”

The way the stator is produced also allows it to have an equal coefficient of thermal expansion in all its surface, which would make it more durable and reliable. If you think the stator seems fragile because it is basically a circuit board, you’re wrong, according to Infinitum’s CEO.

“You look at the car today. It has lots of printed circuit boards already. We are not the first one’s using printed circuit boards in cars. We are just applying them in a different way. We are highly confident in our ability to be as durable and as reliable as traditional ones.”

Infinitum Electric decided to start its commercial career in the heating, ventilation, and air conditioning market. You also know it as HVAC.

“The HVAC industry has a lot of interested customers in the high-efficiency elements of our technology. It is ideal for them. Everything from cars to drones, to propulsion motors, auxiliary motors, its attributes apply very well to electric vehicles.”

The choice was not arbitrary, according to Schuler.

“Our reasoning for starting off in the HVAC market is that is has a rather low barrier to entry. So this allows us to sell 10,000 20,000 100,000 and prove to everyone how durable and high-performing our motors actually are. Having that proof case in the HVAC market will open up lots of other avenues, such as oil and gas, or space, whatever it is. The HVAC launch will enable that.”

What was random was the 1,000 hp limit information on the press release. According to Schuler, its company’s motor can achieve whatever the demand requires.

“The 1,000 hp limit for his motor is just an arbitrary number to talk about the technology. It can go higher than that. In the oil and gas business, these motors are like 5,000 hp. They use huge machines. Most cars would not need more than 300 hp.”

Infinitum’s CEO says the new investment of $12.5 million they announced this December 5 allowed them to enter their new production facility in Austin, Texas.

“We’re going to ship our first products in June of next year.”

There are already some automakers paying careful attention to the printed circuit board stator motor from Infinitum.

“I wish I could share their names. We are in contact with a handful of them, as well as suppliers, to find the best applications in the EV industry. Propulsion, hybrid, auxiliary motor in the car, whatever it is. We are actively working with all of them.”