Toss or Repair? The Impact of Serviceability on Motor Life and Costs

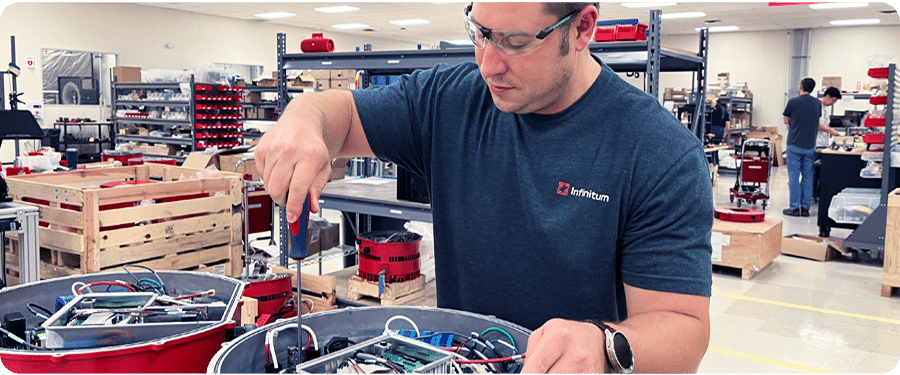

By Cam Witt, Infinitum Product Manager

In today’s throwaway culture, even electric motors aren’t immune. All too often, motors—especially those under 11 kW (15HP) — end up in a landfill rather than being repaired due to service costs and complexity. However, considering a motor’s serviceability – the ease of maintaining or repairing a motor – can play a pivotal role in a motor’s efficiency, longevity, sustainability, and greatly influence their total cost of ownership (TCO). Understanding this concept is crucial when choosing an electric motor. So, what should you consider about serviceability, and which questions should you ask when evaluating motors? Dive in to find out.

Minimize Downtime

High serviceability means less downtime. With the right design, key motor components can be accessed and replaced quickly and efficiently, drastically cutting downtime during maintenance or repair. Rapid availability of replacement parts and technical support can further minimize disruption to operations.

Modularity is also a key factor in motor serviceability. In modular designs, a motor is divided into separate components or modules that can be independently replaced or repaired. This design principle enhances serviceability by making it possible to replace or repair individual components, such as the Variable Frequency Drive (VFD), without removing the entire motor from its application.

When selecting a motor, the following questions can help users evaluate serviceability:

-

- Is this motor built in a way that lets me swap out parts easily?

-

- Can I get spare parts quickly and cost-effectively?

-

- Can parts, like the controller, be replaced without taking the whole motor apart?

Extend Lifespan

Serviceability extends the lifespan of a motor since routine maintenance and repairs are easier to execute. A motor with high serviceability allows individual components to be replaced, eliminating the need for full motor replacement and substantially reducing costs.

Preventive maintenance also plays a crucial role in the lifespan of a motor. Motors equipped with monitoring systems can provide early warnings of potential issues, allowing for proactive maintenance and issue prevention. Such features greatly increase serviceability, prevent more significant issues down the line, and prolong the motor’s life.

The following questions can help users evaluate the lifespan of a motor:

-

- How long is this motor expected to last?

-

- Can this motor tell me when something’s about to go wrong?

-

- Are there guides or resources to help me take care of this motor?

Total Cost of Ownership

Total Cost of Ownership (TCO) is a crucial aspect to consider when selecting an electric motor. TCO includes not only the initial purchase price but also the costs associated with maintenance, repairs, operation, and downtime throughout the motor’s lifecycle. A highly serviceable motor with modular components and easily accessible parts can significantly reduce these ongoing costs. In addition, a motor that can be repaired rather than replaced contributes to lower TCO by reducing the need for potentially costly new motor purchases.

The following questions can help users evaluate the TCO of a motor:

-

- What can I expect to save on operational costs due to this motor’s efficiency?

-

- Does the manufacturer provide support or resources to help minimize repair and maintenance costs?

-

- How does the TCO of this motor compare against a motor that has limited to no serviceability?

Increase Sustainability

Serviceability is also closely tied to sustainability. By facilitating repairs over replacements, serviceable designs reduce waste and support eco-friendly practices. Unlike the more common discard-and-replace approach, repairing or replacing individual components as needed results in less material waste and lower energy consumption during production.

The following questions can help users evaluate the sustainability of a motor:

-

- Can this motor be repaired or reused instead of throwing it away – to help reduce waste?

-

- Does this motor have a remanufacturing process in place?

-

- Can this motor be reprogrammed to fit different configuration needs in the future?

Conclusion

In the world of electric motors, serviceability is a crucial factor affecting efficiency, lifespan, sustainability, and total cost of ownership. By incorporating a modular design and providing comprehensive support and resources, Infinitum motors ensure minimal downtime and extend the lifespan of the motor. Our commitment to sustainability means we favor repair over replacement, thereby reducing waste and supporting eco-friendly practices.

When consumers and industries prioritize serviceability, they can make better choices. This means choosing motors that not only perform well, but also have a longer lifespan and are more sustainable. Infinitum motors are a great example of this, as they are redefining what’s possible in the electric motor industry.

Interested in learning more about Infinitum Aircore EC motor serviceability? Visit our Document Library for articles, guides, videos, and more.