This Week in PowerBites: Motors with Printed Stators, USAF Approves eVTOL

While charting a course through the WBG wilderness, can developments in trains, ePlanes, and…air conditioners…help save the planet?

Author: Lee Goldberg

This article is part of thePower Management Series: This Week in PowerBites

Climate-Friendly, Market-Ready Cooling Technologies Emerge from Global Competition

Winners of the Global Cooling Prize were recently honored for their cooling advances, creating products and technologies that deliver cooling with over 5X lower climate impact. It’s also expected that their reduced operating costs are expected to encourage their adoption in both developed and emerging economies.

The competition was initiated by a global coalition of the Government of India, Mission Innovation, and the Rocky Mountain Institute (RMI). It encourages the development of breakthrough technologies that dramatically reduce the energy consumed by air-conditioning systems, which currently consume at least 10% of the world’s electricity supply—a number that’s expected to increase as the climate warms.

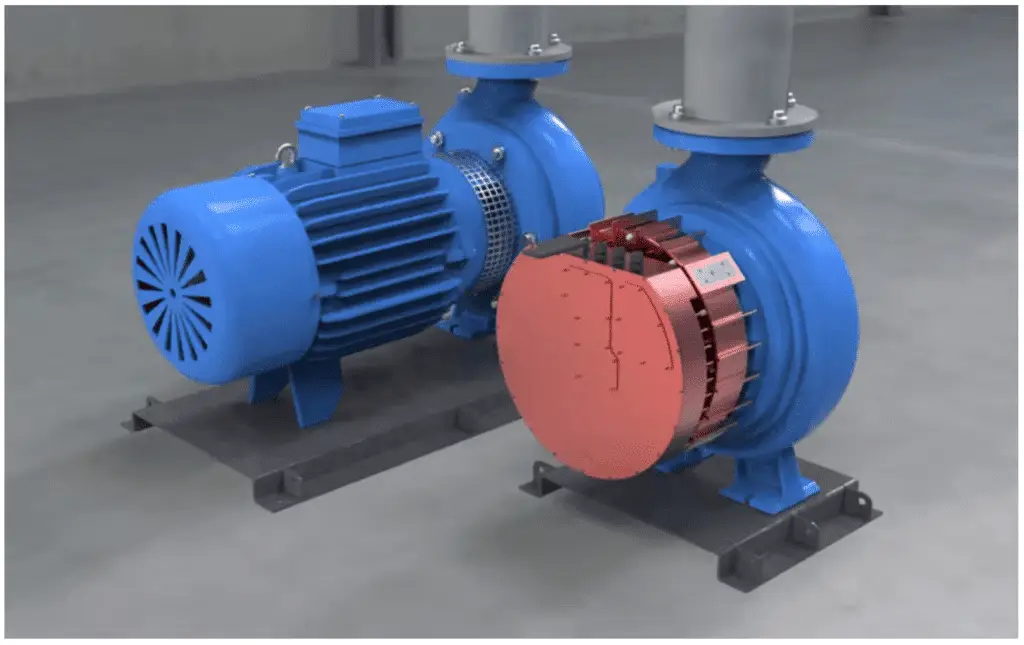

Smart, Ultra-Efficient Industrial Motors Use Printed Stators

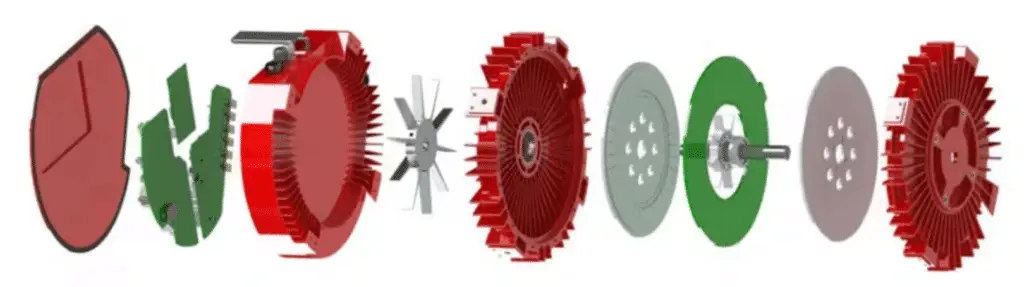

Infinitum Electric expanded the range of power and frame sizes for its IEs Series of motors, now available with outputs from 5 to 15 horsepower, for fans, pumps, compressors, conveyors, and general-purpose applications. The motors feature an air core architecture and a unique printed stator that requires much less copper and virtually eliminates the core losses associated with conventional motors. In addition to being extremely efficient, Infinitum’s architecture is simpler to manufacture and is 50% lighter and smaller than a similarly rated NEMA Premium motor.

The motor’s high efficiency and compact size are the result of a new architecture that replaces conventional motors’ rudimentary iron core and copper wire with a copper-etched PCB. The motor’s reduced core losses and fully integrated variable-frequency drive (VFD) make it among the industry’s most efficient, while its low-torque ripple makes it the quietest motor system on the market, according to Infinitum.

IEs Series motors are fully integrated systems consisting of the motor, a VFD, and embedded IoT combined in a single compact form factor. Their embedded self-monitoring and IoT capabilities make them ideal for smart-building/smart-factory/smart-city applications that require remote monitoring, control, and predictive maintenance.

Infinitum was founded with a focus on high efficiency—the intent is to create cost-effective products that allow their customers to build products offering lower operating costs and lower carbon footprints. Customers currently using Infinitum Electric’s debut model, the IEs205, include Comefri USA, Twin City Fan & Blower, and ACME Fan.

“Infinitum Electric’s expanded product line, compact form factor, and ability to manufacture in North America allow us to rapidly deliver innovative, efficient HVAC systems to our customers who also benefit from easier installation and noise reduction,” said Doug Yamashita, EVP of sales and marketing at ACME Fan.