Proven Efficiency:

Infinitum Motors Outperform Conventional Motors in Wire-to-Water Efficiency

By Stephen Mathew, Infinitum

Having set the benchmark for efficiency in fan systems, Infinitum is now demonstrating equally impressive performance in pump applications. Recent testing at a third-party facility has shown that Infinitum Aircore EC motor systems offer superior wire-to-water efficiency for pump systems. In this test, the Infinitum motor system outperformed a comparable conventional motor by 5-9%, with wire-to-water efficiency improvements across a range of operating conditions. Infinitum motors deliver significant energy savings, reduced operational costs, and enhanced performance, making them the optimal choice for reliable, energy-efficient pump systems.

Pump Applications

Pumps are critical to a wide range of industries- from data center cooling to HVAC and water treatment- where they move water or other fluids efficiently and reliably. In many facilities, pumps operate around the clock, meaning even small efficiency gains can lead to substantial energy and cost savings over time. Matching a high-efficiency motor with the right pump design not only improves performance but also extends equipment life by reducing strain on system components. Infinitum motors are engineered with pump applications in mind, delivering the durability, control, and efficiency needed to meet demanding operational requirements.

Wire to Water Efficiency

The metric represented by wire-to-water efficiency combines the efficiency of the motor, VFD, and pump into one comprehensive measure, capturing the entire system’s energy performance from electrical input to water delivery. It provides a complete view of the system’s performance, enabling better decision-making when selecting components and ensuring the system operates at peak efficiency.

Selecting a motor that is properly sized and compatible with the pump’s performance characteristics (e.g. required flow rates and pressure) is key to optimal wire-to-water efficiency. For example, the motor should be appropriately sized for the pump’s load and efficiency. By considering efficiency data, performance curves, and how the components interact, you can create a pump system that maximizes energy savings and overall performance.

Testing Overview

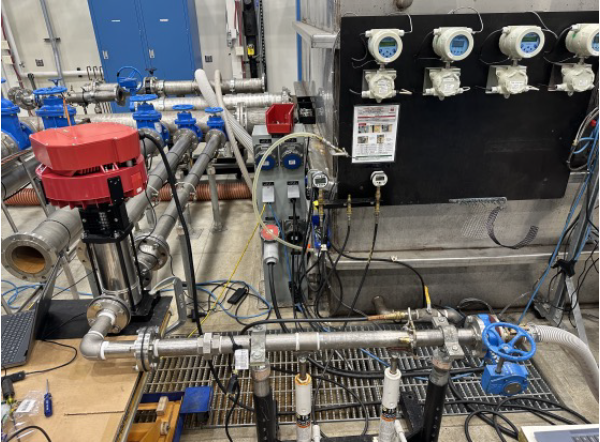

The objective of this testing was to evaluate and compare the wire-to-water efficiency of Infinitum’s Aircore EC motor system against a conventional AC induction motor[1] with a control pump. Both systems were tested under identical conditions to ensure an equivalent comparison. The pump configuration selected- a vertical, shaft-down, multistage inline pump- represents a common choice for applications requiring consistent pressure and flow in a compact footprint, such as water distribution, HVAC, and industrial processes. These pumps use multiple impellers arranged in series to increase head while maintaining a steady flow, making them ideal for high-pressure, low-to-moderate-flow applications.

[1] The AC Induction motor tested was a 5 HP, IE4 efficiency

Testing Methodology

Tests were performed at operating frequencies of 30, 40, 50, and 60 Hz. The drive for each motor system was supplied with 460 V, 60 Hz input power. For the Infinitum system, the integrated drive was measured directly; for the conventional system, an external X-Drive (CXD-010A-4V) was used. Both motor systems drove the same pump to ensure consistent hydraulic conditions. Input power to the drive was recorded to determine total electrical power supplied to the motor and drive combined. Hydraulic output was measured by recording pressure at the pump discharge and monitoring flow in gallons per minute (GPM) using flow sensors. These values were then used to calculate water power based on the pressure differential and flow rate. Wire-to-water efficiency for each operating point was calculated as the ratio of hydraulic output power (water power) to the measured electrical input power to the motor-drive unit, expressed as a percentage.

Photo 1: Infinitum Aircore EC motor mounted in a vertical, shaft-down orientation, coupled to a multistage inline pump during laboratory testing. Pump was a vertical inline pump.

Wire to Water Efficiency Test Results

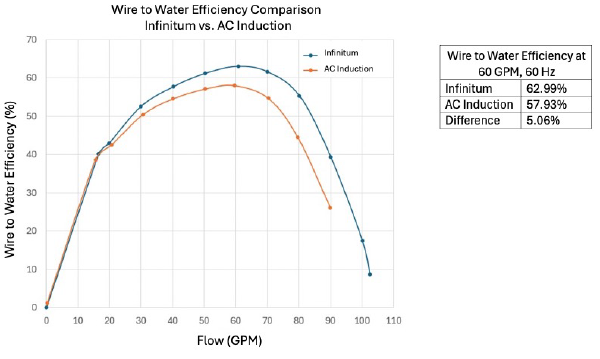

Across all test points, Infinitum’s motor system demonstrated superior wire-to-water efficiency compared to the reference AC induction motor system.

- At 60 GPM, the Infinitum system achieved 62.99% wire-to-water efficiency, a 5% improvement over the AC induction motor’s 57.93%.

- At reduced flow rates of 50, 40, and 30 GPM, the Infinitum system maintained its advantage, with efficiency improvements ranging from 5.4% to 9%.

Graph 1: Wire to Water comparison of Infinitum motor system and AC Induction (IE4, NEMA Super Premium motor + VFD)

These results confirm that the Infinitum Aircore EC motor not only matches high performance at design flow but also sustains efficiency gains at part-load conditions, offering consistent energy savings across a broad range of operating points.

Technology Advantage

Infinitum motors leverage axial flux technology with a thin PCB stator core, providing compactness and higher efficiency. Their integrated approach and advanced materials significantly enhance operational performance and energy efficiency.

Conclusion

The testing conclusively validates that Infinitum’s Aircore EC motors deliver superior wire-to-water efficiency, offering substantial energy savings and operational benefits. This positions Infinitum motors as an optimal choice for applications requiring reliable and efficient pump systems.

Ready to Boost Your Efficiency?

Contact Infinitum today to learn how our innovative motor technology can transform your operations.

Whether you’re upgrading existing systems or designing new ones, our team is ready to help you get started with the most efficient motors on the market.