The Acoustic Advantage of Infinitum Aircore Motors in Data Center Applications

By Amanda Weilenmann, Infinitum

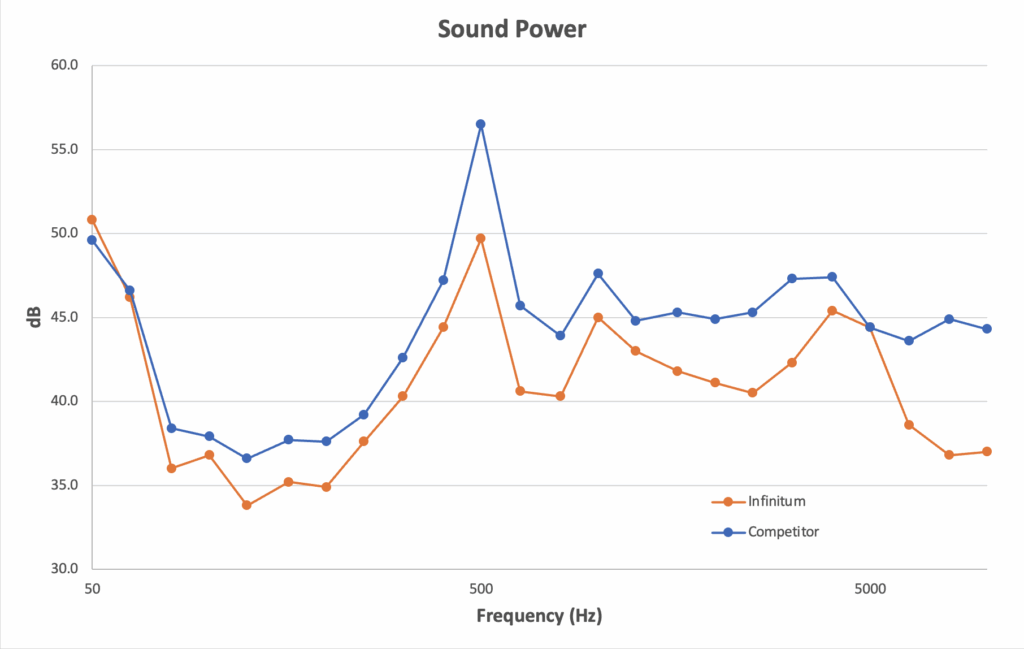

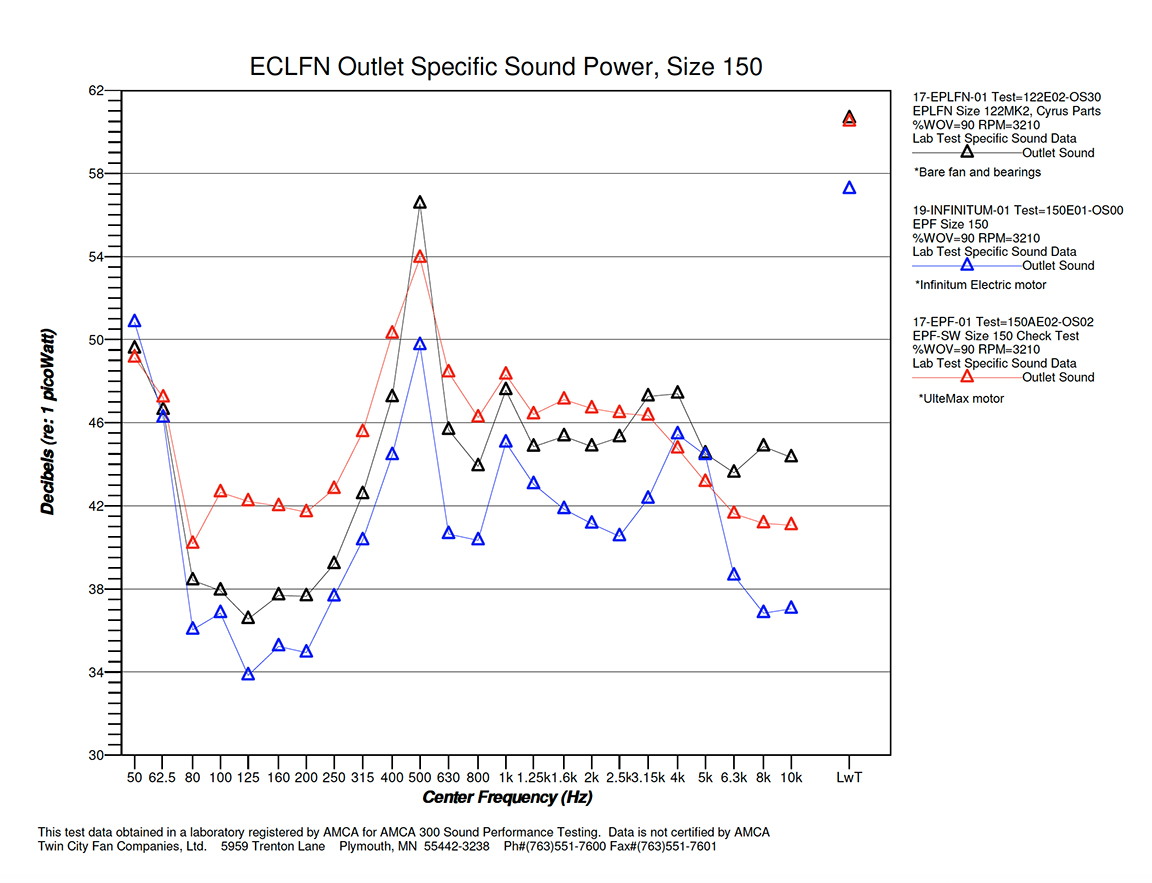

Data centers are increasingly concerned with operational noise, not only for personnel comfort and safety but also to support the reliability of densely packed, high-performance computing environments. This paper details the acoustic benefits of Infinitum’s Aircore EC motors and quantifies the measurable sound reduction compared to conventional motors. Our findings show an average sound power reduction of 3.4 dB, with peak improvement reaching 5 dB, corresponding to a 45% reduction in radiated sound energy. These results offer a meaningful acoustic advantage for hyperscale and colocation data centers seeking quieter, more efficient infrastructure.

Infinitum’s Aircore EC motors deliver up to 5 dB quieter performance—cutting radiated sound energy by 45% for a calmer, more efficient data center environment.

As data center operators pursue operational excellence, acoustic performance has emerged as a critical design consideration. With the proliferation of GPU-accelerated workloads and denser equipment layouts, noise pollution from mechanical systems—especially HVAC components such as motors and fans—can significantly impact working conditions and overall system health. Infinitum’s Aircore EC motors, with their unique printed circuit board (PCB) stator architecture—an innovative design replacing traditional iron cores with circuit board technology—and integrated control electronics, offer a quieter alternative to traditional iron-core motor technology.

Measurement and Methodology

Infinitum conducted controlled sound power level testing. Sound power, rather than sound pressure, was used as the evaluation metric due to its suitability for comparing noise sources in varying acoustic environments.

Results showed:

- Peak Sound Reduction: 5 dB lower than conventional motors

- Average Sound Reduction: 3.4 dB

A 3 dB reduction in sound power equates to a halving of acoustic energy. Therefore, a 3.4 dB reduction means that the Infinitum motor produces just 45% of the sound power of a conventional motor.

Engineering Behind the Quiet

Several factors contribute to the superior acoustic performance of Aircore motors:

- No Iron Core: Eliminates magnetic hum and structural vibration associated with laminated iron stacks.

- PCB Stator: Virtually immune to magnetic forces, eliminates torque pulsation and associated forces.

- Integrated Electronics: Minimizes resonance between discrete components such as external VFDs and motors.

Impact in Data Centers

The acoustic improvement, while seemingly incremental on paper, yields significant real-world value in hyperscale and colocation environments:

- Personnel Safety & Comfort: Reduces exposure to harmful noise levels in walk-in air handling units.

- Equipment Longevity: Lower vibration and acoustic energy contribute to reduced mechanical stress.

- Design Flexibility: Enables more efficient fan wall configurations without additional sound attenuation treatments.

What this means

Infinitum’s Aircore EC motor provides a measurable and meaningful sound advantage for data centers. With a 3.4 dB average reduction in sound power and peak reductions up to 5 dB, this technology supports quieter, more efficient thermal management systems. The result is a superior operating environment that contributes to both human and machine well-being—a small change with a powerful impact.

Ready to reduce noise and boost performance?

Get in touch with Infinitum to explore how our Aircore motors can elevate your data center.